WATER

(Watch out for Leeks in the boat!)

Building a cedar-strip craft takes focus, ambition, and perseverance.

-

Building watercraft in the summer is ideal, but sometimes winter is the only time life slows down enough for large and involved projects.

-

Strips are typically 3/16 of an inch

-

Steam is a common method used to bend wood, but I am working with thin strips so use a heat gun to manipulate the strips with no down-time for drying.

-

Cedar is rot resistant and is lightweight. Plus it is wrapped in fiberglass and epoxy for strength.

-

By ‘fair surface’ I mean that the strips are on the same level. I rip my strips from long cedar boards with a table saw, then run them through a planer. The planer cleans up any blemishes or saw marks from the table saw. A few extra steps on the front-end of the build saves time and effort during the build - and a heap of sanding too!

-

Building a kayak or paddleboard from scratch is a slow process with a sea kayak taking about 200 hours to complete.

With Paddleboards only the outer surfaces are seen, unlike a kayak, so it is a faster build.

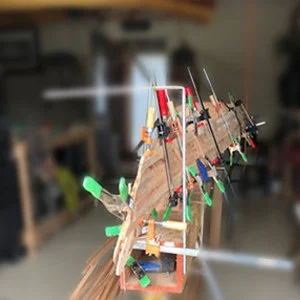

Strongback

-

A strongback is a plywood box beam that hold stations (plywood forms) on which the strips will be added.

Aligning stations

-

Placing test strips keeps the stations straight. These strips are removed once the hull is built up with enough permanent strips.

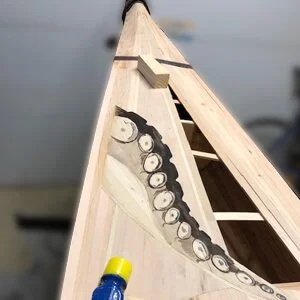

Adding strips

-

Using carpenter’s hot glue to adhere strips to the stations (forms) keeps a clean surface. Stapes are typically used, but leave small holes that I find undesirable. The extra effort using hot glue keeps the deck and hull clean and attractive - seamless!

Paddleboard

Pictured is the ‘from-scratch’ 11’8” stand-up paddleboard on launch-day!

It is incredibly stable and quite fast as well. I took liberties with the build and added a dry hatch. The dry hatch reaches from edge to edge and will store bulky items easily!

Playing in the January 2024 lake ice